Foreign Insulators

by Marilyn Albers

Reprinted from "INSULATORS - Crown Jewels of the Wire", December 1982, page 5

Potheads and Spur Insulators

Collectors of foreign porcelains seem to be generally excited about finding the

peculiar shaped insulator nicknamed the "Pothead". It has a top cover

which unscrews from the rest of the insulator and resembles a jar of peanut

butter with a lid. This insulator design was invented by Colonel Sir T. F.

Purves and J. Sinnott of London, England, covered by U.S. Patent #898,921,

September 15, 1908, and first introduced at that time in England. English

manufacturers were Bullers Ltd. (London) and Taylor Tunnicliff and Co. (Hanley).

In the U.S. we would call this design a "dry spot" insulator. In

England it is referred to as a terminal insulator. Quoting from Worldwide

Porcelain Insulators, co-authored by Jack H. Tod and myself, "Styles vary

as to one or two holes for lead in wires, etc. The purpose of these insulators

is to provide a "dry spot" on the insulation of the lead-in wire,

thereby breaking the wet weather shorting path from the line wire over the

insulation of the lead-in wire to ground." It provides the cheapest and

most efficient method which has ever been devised of connecting aerial wires to

covered leads.

Quoting now from some xeroxed material sent to me by Alex Burnett

(Vermillion, Alberta, Canada), which I believe was taken from a book called

Telephony (author ?), "The connection between the open wire and the covered

lead is made in a cavity formed at the top of the insulator; this cavity is then

filled with insulating compound and covered by a screw cap. In this way a

lead-covered cable may be carried up to the insulator, where the end is

effectively sealed by the compound. Telephone subscribers' circuits are led in

with lead-covered cable having 2-wire enameled and F.P.-covered 10 lb.

conductors.

"The insulating compound is soft enough to be pressed cold into

the insulator top and is not materially affected in consistency by changes of

temperature met with in practice. It has a high insulation resistance when dry,

and this is maintained when in contact with water. Its composition is by weight:

56% French chalk (magnesium silicate), 32% Palm pitch and 12% coal tar.

"The compound should be thoroughly pressed into the cavities of the

insulators so as completely to enclose the bare wire joints, care being taken to

see that the cavities are quite dry before it is put in."

A couple of my

pothead insulators from England do have this strange putty-like substance in

the top cavity, and it was so interesting to me to learn what it was made of and

why it was there!

These insulators were made of white glazed porcelain or black

composition. Depending on the size of the insulator, the small threaded pinholes

were made to screw directly onto either a 5/8" or a 3/4" steel spindle

(pin).

One other manufacturer of the "pothead" insulator was Sunshine

Porcelain Potteries of Melbourne, Victoria, Australia. According to information

coming from Laura Van der Endt and Dawn Hole, who both live in Australia, this

company sold to a switchgear manufacturer which eventually ceased all

manufacture of porcelain products. Apparently other styles of insulators had

been made as well. I have no other information about Sunshine Potteries, i.e.,

history, dates, etc. However, the pothead insulator I have with their trademark

is dated 1934.

A Swiss company known as Suisse Langenthal also produced the

"pothead" insulator, as well as many other styles of insulators, and

is possibly still in business. We have no other information about this company,

not even where in Switzerland it was located. Can you help? Specimens we

borrowed from Steve Watkins (Portland, Oregon) and Joe Tuma (East Islip, New

York) for drawings were dated 1953 and 1954 respectively.

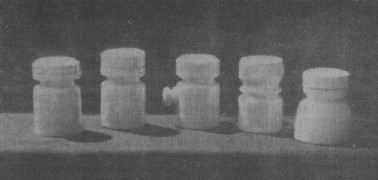

The picture below

shows several variations of the "pothead" insulator.

Viewed from left

to right we see examples of the following manufacturers:

- Taylor Tunnicliff

and Co.; incuse trademark on top of lid; patent dates on skirt. (A new variation

and as yet no U-number assigned.)

- Sunshine Potteries; incuse trademark on

lid: This is U-1938.

- Taylor, Tunnicliff and Co.; known as a terminal

"spur" insulator. This is U-1944.

- Unidentified English

manufacturer; incuse letters G.P.O. (General Post Office) plus a

"hand" trademark on the skirt. This is U-1941, known as a double

groove "pothead".

- Suisse Langenthal -- trademark stamped in green

ink up inside skirt. (New variation, not yet classified.). Insulator borrowed

from Steve Watkins.

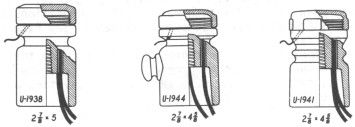

Following is a picture of several variations of the

"pothead" in black composition.

Again reviewed from left to right:

- Manufacturer unknown; raised letters G.P.O. on Lid; probably English.

- Manufacturer unknown; raised figures on lid are: NO 16 -- L R; found in New

Zealand, but probably English.

- Manufacturer unknown; marked: NZPO 69 (New

Zealand Post Office); double groove "pothead" made of hard rubber --

extremely light weight; found in New Zealand.

- Manufacturer unknown; raised

letters: LEA NZPO 62; double groove "pothead"; found in New Zealand.

Spur insulators:

One particular design of "pothead" had a side knob,

and in the first picture I showed you it is #3, and is referred to as a

"terminating spur insulator". It is the white porcelain insulator

right in the center. It came into use some time between 1912 and 1920. The

British Post Office referred to it as their insulator #21. Still another British

design of spur insulators is their #10, described as "a small double

groove, double shed, Sinclair (patent name) insulator with side knob for a

5/8" "spindle". It was introduced before 1907 and was at first

available in either white porcelain or black composition. It was not until

sometime between 1946 and 1955 that brown porcelain was added to the list. The

example shown in the picture below is our U-1578, and it is brown!

Again

quoting from our Worldwide Porcelain Insulators book, "Spur insulators are

for applications where the direction of a wire abruptly changes from a

horizontal to a vertical route. Also similarly, when a tap line is taken off the

through line either vertically or nearly so. The reason this side knob also

appears on some designs of "dry spot" (pothead) insulators is that the

lead-in wires nearly always run vertically."

|